If you are looking for free plans with which you can make your own CNC machines, we have searched for you and selected the best quality ones.

Mostly these are plans for making CNC routers, 3-axis CNC machines, and the like. If you, too, have come across some quality plan on the Internet, feel free to let us know, and we will include it in this collection of projects for making CNC machines.

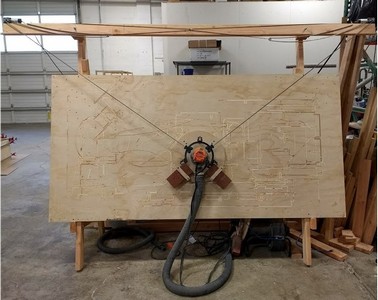

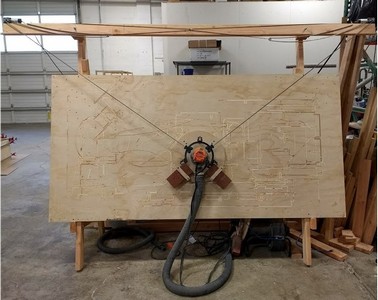

- Maslow CNC router project

The goal of the Maslow project is to make CNC accessible to everyone. That means making a machine which is affordable, requires no special tools or skills to assemble, and which is easy to use. We've done our best to create a design which we think works towards achieving these goals, but we know that an even better machine is possible with your help. Your feedback about how to make these directions better is more than welcome.

Building the machine is done in five steps. The directions for each step are in the respective GitHub wikis which you can edit. We chose to do the instructions this way to ensure that the directions are always up to date, and as clear as possible. Maslow CNC is an open-source CNC router project. It is the only commercially available vertical CNC router and is notable for its low cost of US$500.

- CNC Router Plans

CNC router plans are a great starting point for anyone wanting to build a CNC router. They give valuable insight on how these machines work. Many of us are very visual people and it helps to see examples of these machines laid out on paper. Some plans are thorough enough to act as a complete blueprint from start to finish while others only offer bits of information.

You may prefer to design and build your own machine. However, CNC router plans can still be a valuable resource. Plans can give you great ideas. You may like the linear motion system on one design but prefer the cutting bed design on another. They may also uncover aspects of your design that may or may not work.

This is why we want to provide you with as many free plans and blueprints as possible. There several companies devoted to providing plans you can buy. Some are worth while, and others are not. At the moment, we are working on several free plans complete with pictures, 3D and 2D downloads, and even videos.

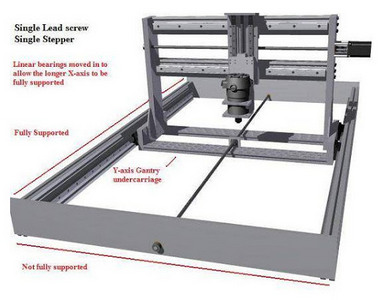

JGROs Design

This design is very popular among the DIY CNC router community. This set of plans is very detailed and contains dimensions on all parts. This is a mobile gantry type designed around a wood or MDF construction utilizing skate bearings for the linear motion system. This build can be very sturdy if built correctly. The set of plans also contains a complete BOM (bill of materials).

Joes 2006 R-1 Design

This is another very popular design. This design is also a mobile gantry CNC router, designed around a wood or MDF structure. The linear motion system is also design around skate bearings. However, the x-axis employs dual rods and each side instead of one. This design is very ergonomic looking and employs anti-torsion framing and slanted gantry side arms to account for CG location.

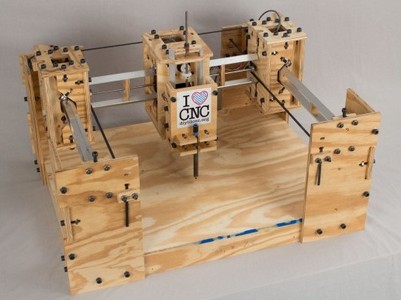

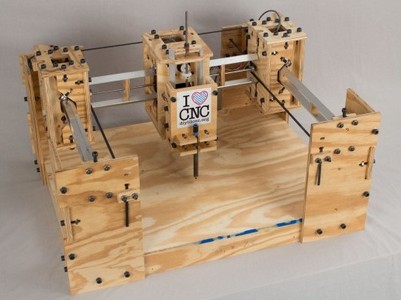

- DIYLILCNC Project - 3-axis CNC mill

The DIYLILCNC project is a free & open-source set of plans for an inexpensive, fully functional 3-axis CNC mill that can be built by an individual with basic shop skills and tool access.

CNC devices are used to fabricate physical objects with a high degree of precision. Some CNC devices, including the DIYLILCNC, feature a gantry-mounted cutting tool (like a router) that can move in two or more directions. The operation of the tool is controlled by a computer, which is tasked with translating a digital design into actual tool movement.

The DIYLILCNC can be built for around $700. This cost includes all the stock hardware and sheet material used in construction. CAD files for custom laser-cut parts are distributed along with the plans. Anyone with access to a laser cutter can use these files to fabricate all the panel parts necessary for construction; those without ready laser-cutter access can purchase laser-cut panel kits on our Buy page, or give the files to a local or online laser-cutting service.

Plans and instructions for building the DIYLILCNC are distributed freely and intended for wide distribution and modification with few restrictions. The plans are formatted to facilitate easy fabrication, especially for beginners. The DIYLILCNC can be built by an individual, a student group, or a class. Besides being immensely fun, building the DIY LIL CNC is a great way to learn about motion control and CAD/CAM/CAE.See a brief overview of the DIYLILCNC project in the video to your left.

- Computer controlled router 'Otocoup'

These drawings are supplied freely for amateur us.

- Specifications of machine as on plans

- Total width 3.20 m, range 2.60 m

- Height 2.00 m, range 1.60 m

- Depth range 90 mm

- Router : prefer Kress FM6990 E (in Europe)

- I beam weight : 10 kg

- Carriage weight without router : 4 kg

- Main beam (vertical) and horizontals beam made with mason ruler 100 x 18 x 1

- Roller bearings, ABEC1

- HTD type timing belts carrying

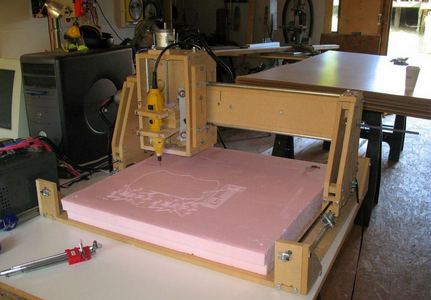

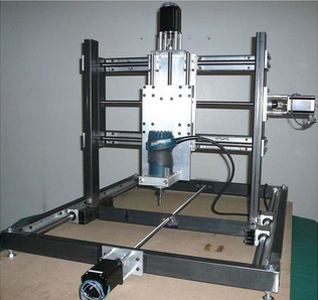

- How to Make a Three Axis CNC Machine

The idea behind this Instructable was to fulfill my desire for a desktop sized CNC machine. While it would have been nice to purchase an off the shelf unit the issue of price as well as size proved prohibitive. With this in mind I endeavored to design and build a three axis CNC machine with the following factors in mind:

-Use Simple tools (needs only a drill press, band saw, and hand tools)

-Low Cost (this kind of got away from me however with everything bought off the shelf the cost for all parts is under $600 (significant savings could be made by skillfully sourcing some pieces))

-Small footprint (30" x 25" footprint)

-Usable working envelope (10" X-axis, 14" Y-Axis, 4" Z-Axis)

-Relativly fast cut rate (60" per minute)

-Small part count (fewer than 30 unique parts)

-Easy to source parts (all parts available from 4 sources (Home Depot + 3 online sources)

-Ability to cut ply-wood (Succesful)

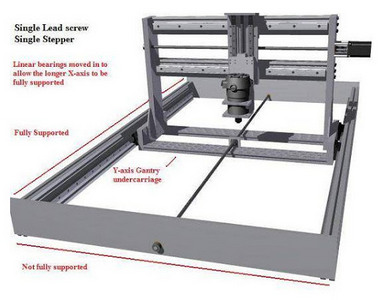

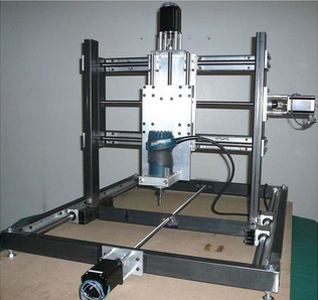

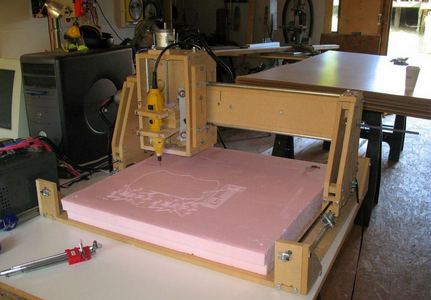

- DIY CNC Router

This instructable will show you how to construct a CNC Router that will allow you to cut 3-D shapes out of wood, plastic and aluminum using a standard hand held router. Recently I have noticed that more and more projects on instructables have involved the use of some sort of CNC machine, be it a laser cutter, 3d printer, milling machine, etc. I wanted to join this revolution of digital fabrication and start making my projects even better using these tools. So about a year ago I set out to find a way to make this possible and came to conclusion that a simple 3 axis CNC router would be the best option to get things going. I started doing some research and decided to design and build my own machine. This instructable steps though all the parts needed to build the machine I have designed and the reasoning behind why I built the machine the way I did. It also includes an explanation of CNC technology and would be a great reference for anyone looking to learn some metal fabrication skills. My hope is that someone might use these plans to build this router for themselves or at least draw some inspiration from my design. I have created 2d drawings of all the parts with complete dimensions and specs, details on how to build each part, a complete parts and tools lists with prices and links, a basic wiring diagram and an explanation of the design.

For those of you who already know about CNC routers here are the specs for my machine.

- Travel: X-Axis 23in

- Y-Axis 13in

- Z-Axis 6in

- Linear Guide: Fully Support Round Linear Rail and Mounted Bearings (20mm, 16mm, 12mm)

- Linear Drive: 1/2”-10 5 Start Precision ACME Screws and DumpsterCNC Anti-Backlash Nuts

- Drive Motor and Controller: Gecko G540 Controller with Gecko 280oz-in NEMA 23 Stepper Motors

- Construction: Welded 1”x2” Steel Tubing and 3/8” Thick Aluminum Plate

- Spindle: Bosch Colt Trim Router

- Rapid Speed: 200ipm (inches per minute)

- Cutting Speed: 1/4" end mill, full width cut, 0.100" depth of cut, 50ipm, material - hardwood (This is a fairly easy cut and is probably less than half the true cutting capacity)

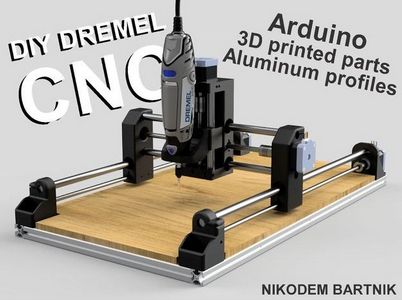

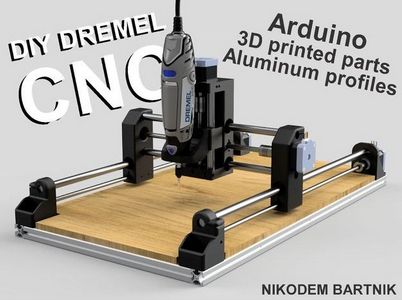

- DIY Dremel CNC design and parts

DIY CNC machine is a very popular project on the internet, a lot of people made different versions but I want to show you how I made my own CNC machine with a Dremel as a spindle. Personally, I think that CNC machine is kind of an upgrade of a 3D printer, you can create stronger parts made out of wood or metal but it also has some limitations.

What we will need, amount in:

-Dremel tool

-Aluminium Profiles 20x20x600mm

-12mm rod

-500mm long trapezoidal lead screw

-300mm long trapezoidal lead screw

-12mm linear bearing

-5 to 8mm coupler

-T nut

-Screws

-Arduino+CNC shield+stepper drivers

-Power supply

-Stepper motors

-Relay

-Limit switches

-AC IEC socket with switch

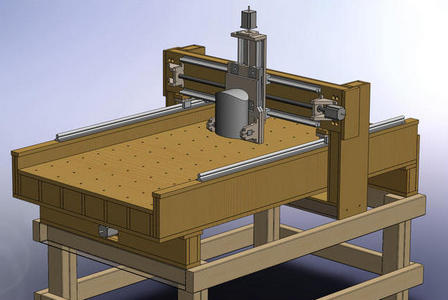

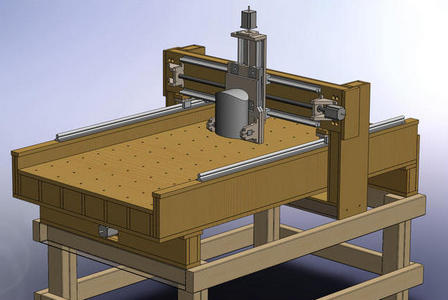

- 3 axis CNC router MDF

This CNC router machine is possible to make with just some hand & power tools.

The machine uses chinese linear rails and ballscrews from ebay. With the 1.8Nm stepper motors I use with geckodrive g540 it achieves 10m/min rapids and 5m/min feedrates. The working area is about 110cm x 60cm x 10cm.

Expected cost to build a machine like this from scratch is 1000-1300 euros. It also took me over 80 hours to build.

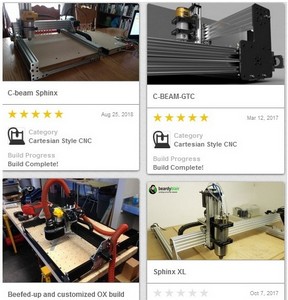

- CNC Router build

Open Builds - Open Source Hardware distribution Sharing Site Dream it - Build it - Share it. OpenBuilds.com is a new community driven project design and collaboration website